- Storyboard SINFONIA 480 SE -

To enlarge the pictures, click on them

The making of my special custom-made design edition Böhm SINFONIA 480 SE

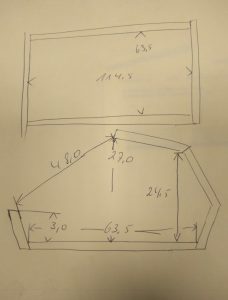

On photo 5 you can see the two ready trimmed boards for the lower parts of the console and the seating bench. The two holes in the front plate, are later used to fix the pillars on the seating bench.

In the rear plate for the console lower part, three holes will be made. The third

hole is necessary for a cable which will later be used to connect the two swell pedals, the four foot pistons and the 25-keys pedal.

June 2018

My Diamand 350 CT (the former show and concert instrument of the late Mark Shakespeare) is standing here on the still untreated steel pillars, which I had made by an art metalworker (Photo 16).

The black colour results from the fact that the pillars have not yet been ground and polished.

Photo 17 shows the console of my SINFONIA 480 SE with provisionally fixed keyboards and still empty control panels. The upper control panel is the one of a SINFONIA 480. It only serves as a "placeholder".

The upper part of the case as well as the lower part do not have the final varnishing yet. The steel columns are packed in

plastic bags to protect them from damage. They are now ground and polished.

August 2018

Photo 19 shows the gold pillars mounted on the console stand lower part.

The positions for the drill holes of the four foot pistons into the lower part are now marked and placed. In front of the lower part you can see one of the pistons. The green area is the contact board for connecting the electronics.

August 2018

The ready varnished cabinet is already equipped with the boards for the AMADEUS Sound Systems, the preamplifier (in the carrier system), the Crystal Mixer, as well as the power supply. All cables have been installed correctly by Martin Lutz, as it should be.

The ZE board is mounted on the left side of the rear side. To the right you can

see the longish board with the audio ports. In the left corner of the case the USB hub is mounted. In the right rear corner XLR connectors for connecting two microphones are embedded in the bottom of the case (Photo 21).